For over a year, I’ve been searching on-and-off for a source of custom acrylic templates for cutting quilting fabric. After a few failed attempts at placing an order with two manufacturers in Norway, I found The Sewing Fools on a Facebook group and placed my first order with them. I had the templates shipped to a friend in the US and picked them up while on a business trip to California.

It’s not sustainable or convenient for my business to order overseas, and it’s unlikely I’ll ever move enough product to justify massive orders with big manufacturers for a discount. So I've been on the hunt for other options.

(image from visitløkka.com)

This week, I stopped at Fellesverkstedet to take a look around. Fellesferkstedet is a makerspace in the Grünnerløkka neighborhood of Oslo. The guy at the front desk was great - he immediately offered to take my husband and me through the facilities to check out their machinery.

I confess that I tuned out for much of the wood shop equipment tour. Table saws, routers, CNC machines, planers - their resources looked amazing, but I have no context for those things. I think my husband was drooling though...

I perked up tremendously at the silk screen machinery. And my eyes sparkled at the sight of a printing press just past the silk screen room.

But the real gem of the tour for me was the laser cutter.

Fellesverkstedet does not require a membership. You make an appointment to come in. They train you to use the machines, and then they leave you to do your work. The next day, I came back and Jens trained me on the laser cutter and the connecting PC. He explained the details of how to format my files in Illustrator and how to set up the machine, as well as the safety shut off and location of the extinguisher should something catch on fire. This is less likely with plastic than wood, but it’s good to be prepared.

For me, the process looked something like this:

- Find a source for acrylic. In my case, it was a local hardware store called Jula. I spent about $33 USD (299 NOK) on a sheet of plexiglass 1000mm x 500mm x 4mm. I would have preferred 3mm, but the options available at my location were 2 or 4mm. If I continue making templates, I'll find another source that carries exactly what I want at a better price point.

- Create a RGB file in Illustrator. (CMYK will not communicate correctly with the laser cutter). The working space of the Fellesverkstedet laser cutter is 640mm by 460mm. You can either create an art board that size, or in my case, I created 2 art boards that were 500mm x 400m, and one that was 500mm x 200mm.

- Set all the cut lines on the shapes so the stroke was .001 pts and red (R=255, G=0, B=0).

- Set all the vector etch lines to .001 pts and black (R=0, G=0, B=0).

- Set the fill on relevant shapes to black. (raster etch lines). Most of my raster etching was in my logo, but I also changed my font to an outline rather than load a new font onto the computer attached to the laser cutter. Those were raster printed.

- Place the material onto the laser cutter, using the ruler guides to align the top and left sides of the material. When etching (not just cutting), remove the plastic film on the top of the plexiglass to keep the etching precise. If the etching needs to be on the bottom of the ruler, mirror the etching layers in Illustrator so everything is backward.

- Turn on the exhaust system that processes the fumes during cutting.

- Autofocus the laser cutter so the cutting device knows where it is in relation to the material being cut. There’s a small mechanism that snaps to the cutter head for this purpose. It lowers onto the material, depresses the mechanism, then retracts up, registering the distance between the material and the cutter.

- Send a small test shape to print. Open the print settings and set the speed based on your material. The slower the laser moves, the deeper it cuts into the material. Running the laser too slow will be unnecessary. Time spent running the machine equals money, so it’s best to be efficient with the laser cutting speed. Default speed on that machine has been set to 1.5. For 4 mm thick plexiglass, a speed of 1 was almost perfect, so we dropped it 20% to .8 and the pieces were almost falling out when I pulled out the sheet at the end. (They were held slightly by the plastic film left on the back). Similarly, slowing down the speed of the black areas in the Illustrator file will etch shapes deeper into the surface.

- Send the rest of your shapes to print. The print settings remain for each subsequent print of your file, but if you open a new file, remember to change the settings from the default position.

There are a few steps I’ve glossed over for brevity, but hopefully this demonstrates a good overview of what’s involved. Several people on Instagram messaged to say their public libraries have laser cutters. This resource is becoming more and more common which is exciting!

It’s not rocket-science, but it’s best to allow enough time and materials to make some mistakes while learning. I spent four hours at Fellesverkstedet, but most people will probably work a bit faster than me. I tend to double check things excessively, but even still, I got confused and thought my print settings would be the same even when opening new files. I had a whole print job that failed. I managed to salvage a bit, and then made another mistake which meant that sheet just needed to be tossed.

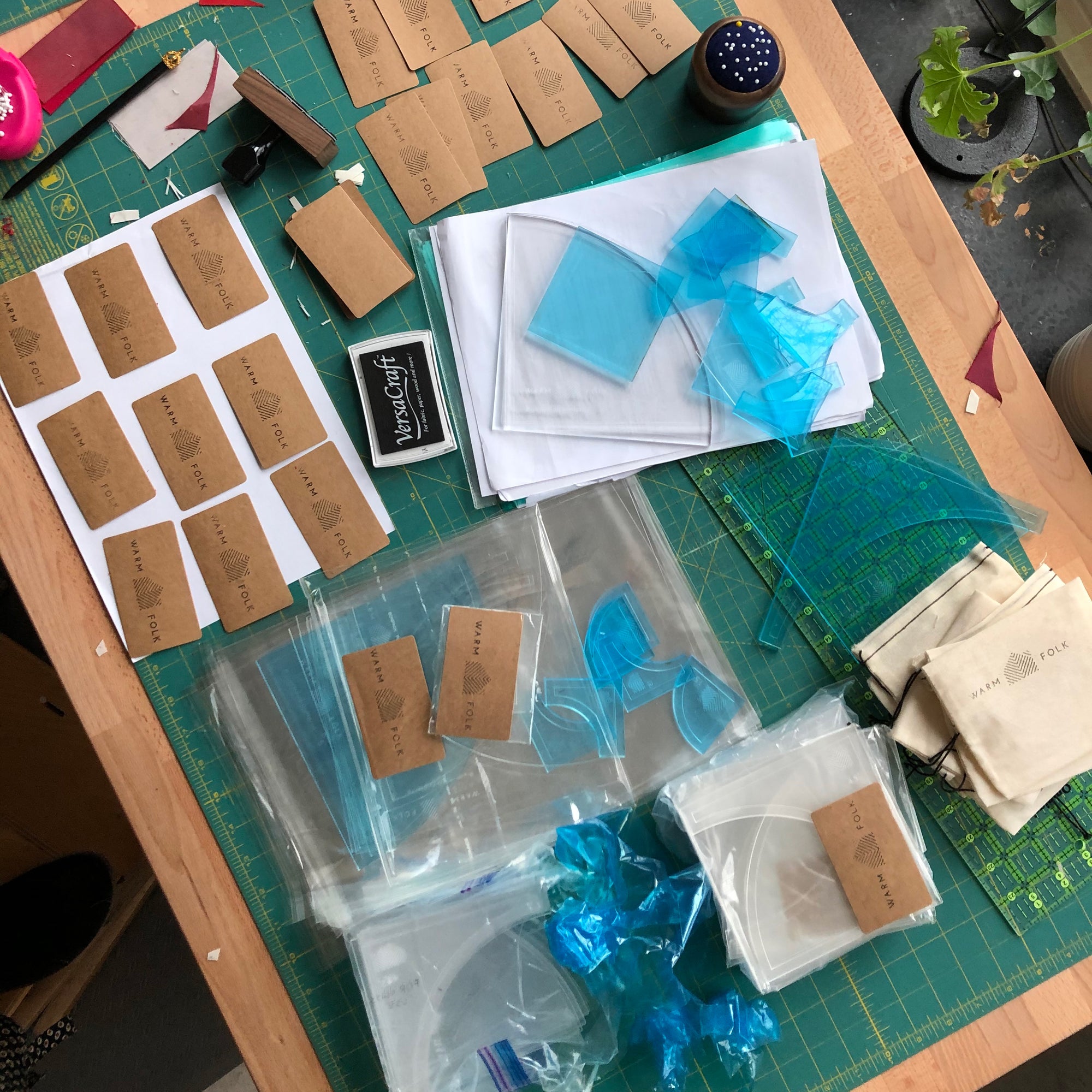

But I had two sheets that were perfect, and I was able to have templates to bring with me to my trunk show at Tåsen Quiltelag on Wednesday night. Being able to print small batches as needed is a huge help for my business, so I’m grateful for the grant money and the fantastic people that keep the doors open at Fellesverkstedet!

Comments

http://mewkid.net/when-is-xuxlya2/ – Buy Amoxicillin Online Amoxil sgh.fvrs.warmfolk.com.ltb.rn http://mewkid.net/when-is-xuxlya2/

http://mewkid.net/when-is-xuxlya2/ – Amoxicillin 500 Mg Amoxicillin yek.lxcl.warmfolk.com.sjs.mv http://mewkid.net/when-is-xuxlya2/